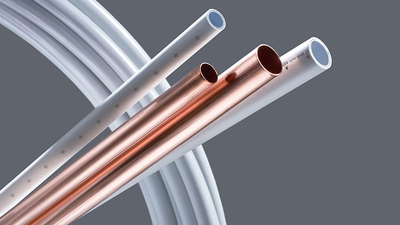

When it comes to plumbing, the materials behind your walls and beneath your floors are just as important as the fixtures you see. Among the most common materials used in residential and commercial plumbing are copper and PVC (polyvinyl chloride). Each of these materials has distinct qualities that affect performance, durability, cost, and ease of installation. Understanding the key differences between copper and PVC piping helps homeowners and contractors make informed decisions based on needs, budget, and long-term plans.

Understanding the Nature of Copper Piping

Copper has been a trusted plumbing material for decades. Its long-standing use in homes and businesses is largely due to its excellent durability and reliability. As a metal, copper is naturally resistant to bacterial growth, making it a hygienic option for water supply lines. It’s also capable of withstanding high water pressure and extreme heat, which makes it a suitable material for both hot and cold water lines.

Copper has been a trusted plumbing material for decades. Its long-standing use in homes and businesses is largely due to its excellent durability and reliability. As a metal, copper is naturally resistant to bacterial growth, making it a hygienic option for water supply lines. It’s also capable of withstanding high water pressure and extreme heat, which makes it a suitable material for both hot and cold water lines.

Another valuable characteristic of copper is its longevity. When installed correctly and under ideal conditions, copper piping can last for more than 50 years. It does not sag over time, and it offers a consistent internal diameter, which helps maintain steady water flow. These properties make copper an attractive choice for those who view plumbing as a long-term investment.

However, copper isn’t without drawbacks. It is more expensive compared to other materials, and prices can fluctuate with market conditions. Additionally, copper installation typically requires soldering, which involves open flames and a greater level of expertise. In older systems, there is also a potential for corrosion if water is highly acidic, although modern water treatment systems often mitigate this risk.

The Rise of PVC in Modern Plumbing

PVC has revolutionized plumbing in recent decades. This lightweight, durable plastic material is widely used for both drain-waste-vent (DWV) systems and cold water lines. Its ease of installation has made it a popular choice among DIYers and professional plumbers alike. PVC doesn’t require any welding or soldering; instead, pipes are joined using solvent cement, which makes for a quicker and safer installation process.

PVC is also resistant to corrosion, scaling, and chemical degradation. This makes it particularly suitable for applications involving wastewater or corrosive materials. Additionally, PVC is significantly more affordable than copper, which can make a major difference in the cost of a plumbing project, especially for larger-scale constructions.

Despite its many advantages, PVC does come with limitations. It’s not suitable for hot water lines unless a variant such as CPVC (chlorinated polyvinyl chloride) is used. PVC also tends to be more brittle in cold temperatures and can crack under stress or impact. Furthermore, while PVC is generally long-lasting, it doesn’t have the proven decades-long track record of copper in terms of lifespan and performance under pressure.

Comparing Durability and Longevity

Durability is often a deciding factor when selecting plumbing materials. Copper stands out for its ability to withstand extreme temperatures and pressures, along with its resistance to UV rays. It performs well in both indoor and outdoor applications, though it may still need insulation in freezing climates to prevent bursts.

PVC, while durable in its own right, does not hold up as well under extreme heat or cold. Prolonged exposure to UV light can weaken its structural integrity, making it unsuitable for outdoor applications without proper protection. For internal plumbing where environmental exposure is minimal, PVC performs admirably, but in more demanding scenarios, copper usually has the edge.

Cost Considerations and Budget Planning

The cost difference between copper and PVC is substantial. Copper’s higher price point can significantly increase the overall cost of a plumbing installation, particularly in large buildings or full-home renovations. The material itself is expensive, and the labor cost associated with copper installation is also higher due to the need for soldering and specialized tools.

The cost difference between copper and PVC is substantial. Copper’s higher price point can significantly increase the overall cost of a plumbing installation, particularly in large buildings or full-home renovations. The material itself is expensive, and the labor cost associated with copper installation is also higher due to the need for soldering and specialized tools.

PVC offers a much more budget-friendly option, both in terms of material and labor. Its ease of handling and quick installation reduce the time and cost required for a plumbing project. For many homeowners working within a limited budget, PVC presents a practical alternative without sacrificing essential functionality.

That said, the lower upfront cost of PVC doesn’t always equate to better long-term value. Copper’s extended lifespan and proven reliability may provide a better return on investment over several decades, especially in homes where future renovations are unlikely.

Water Quality and Health Impacts

Plumbing materials can influence the taste and safety of drinking water. Copper has natural antimicrobial properties that prevent bacteria from thriving inside the pipes, making it one of the safest options for potable water. While extremely high levels of copper in water can be harmful, regulated municipal water systems ensure that copper piping remains safe for consumption.

PVC does not corrode or leach metals into the water supply, which also supports water quality. However, there have been concerns regarding the leaching of chemical additives used in PVC manufacturing. While modern PVC pipes are considered safe for water supply lines, especially when certified by national plumbing standards, they may still impart a slight plastic taste to water, particularly if the pipes are newly installed.

For those particularly sensitive to taste or concerned about potential contaminants, copper might feel like a more reassuring choice. However, PVC still meets safety standards for potable water in many jurisdictions and continues to be widely used in residential applications.

Ease of Installation and Flexibility

From an installation perspective, PVC often wins the favor of plumbing professionals and DIY enthusiasts alike. It is significantly lighter than copper and easier to cut and fit. The solvent welding process used with PVC is straightforward and doesn’t require flames or advanced skills. This allows even novice homeowners to carry out minor plumbing repairs or installations with relative ease.

Copper, while more labor-intensive, offers a tighter, more secure connection when soldered properly. The process is more technical, and mistakes can lead to leaks or pressure issues down the line. That said, many professional plumbers are still highly trained in copper installation, and its durability often justifies the added complexity.

PVC also offers greater flexibility when laying out complex plumbing networks due to its range of fittings and ease of customization. In homes with unique architectural constraints or remodeling projects with tight spaces, PVC can often be maneuvered more easily than rigid copper piping.

Environmental Impact and Sustainability

Environmental considerations are increasingly influencing construction decisions. Copper is a natural material that is 100% recyclable, making it a more sustainable choice in the long term. Reclaimed copper can be reprocessed without loss of performance, reducing the environmental footprint of new plumbing installations.

PVC is derived from petrochemicals and is not biodegradable. While it is possible to recycle PVC, the process is more complex and less common than metal recycling. The manufacturing of PVC also involves chemicals that raise concerns about emissions and environmental harm. However, because PVC requires less energy to produce and install, some argue that it still has a favorable environmental impact when compared to metals that require extensive mining.

When considering sustainability, the end-of-life recycling potential of copper tends to make it a greener option overall. Nonetheless, improvements in PVC recycling technologies may narrow this gap in the future.

Performance in Different Applications

The choice between copper and PVC often depends on the specific requirements of a project. For hot water lines, copper is clearly the superior choice unless CPVC is used. For cold water supply lines and drain lines, both materials are viable, with PVC often preferred due to ease and cost.

In commercial buildings or multifamily residences, where water usage and system complexity are greater, copper’s performance under pressure and temperature variations makes it the preferred material. For smaller-scale residential projects or additions, PVC is frequently chosen for its convenience and affordability.

In some cases, hybrid systems are used, combining the strengths of both materials. Copper might be used for the main supply lines while PVC is installed in secondary branches or for drainage systems. This blended approach can provide both performance and savings when used strategically.